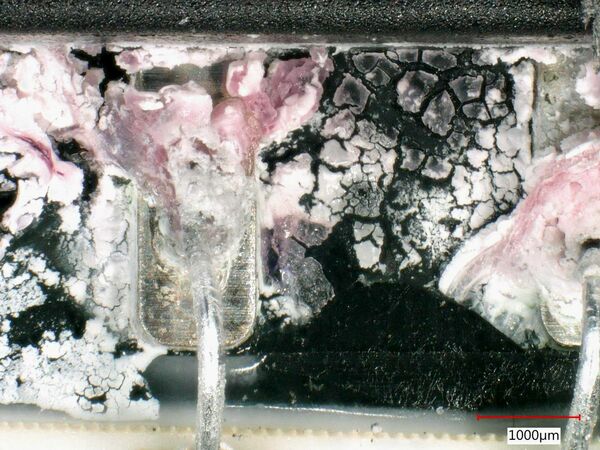

When analyzing corrosion, the main focus is always on material analysis. As well as examining corroded surfaces using SEM-EDX, XPS, and other surface analysis methods, we primarily use metallographic techniques.

With many years of experience, we specialize in analyzing types of corrosion. Our experts have well-grounded expertise in electrochemistry and the physical properties of materials, which is essential for identifying causes of corrosion.

Precisely determining the causes of corrosion damage is often crucial in preventing future corrosion as it enables appropriate measures to be taken.

Corrosion is one of the most important failure mechanisms, especially with metallic materials. According to a study, economic damage caused by corrosion equates to 3–4% of the gross domestic product of developed countries. Many types of corrosion result from errors in planning or application.

However, experience shows that even with the most careful planning, it is rare to predict every eventuality.

Corrosion damage can be caused by unforeseeable influences:

One of our core areas is the analysis of corrosion damage.

Material identification; fracture surface & elemental analysis on surfaces and sections

Material identification; checking of deviations from the nominal composition

Qualitative and quantitative phase analysis of material and coating

Examination of the surface chemistry; determination of the oxidation states of the elements involved

Chemical elemental analysis on the corrosion product or on the material

Identification of contamination or filmic residues

An overview of other methods at the Dresden location